Robot Toolkits for deformable component manufacturing

The Mission

RTForm is dedicated to commercializing innovative solutions designed to automate the manufacturing of non-rigid products, with the following objectives:

To successfully achieve these goals, RTForm provides three specialized and fully integrated toolkits, each designed to address key aspects of automation, efficiency, and sustainability in the manufacturing process.

Human-Robot Flexible Material Co-Manipulation Toolkit (CMT)

Intuitive AR-Based Operator Support Module (OSM)

CAD-Based Robotic Handling and Trimming of Textiles (RTrim)

Industrial Use Cases

Composites Use Case

This use case focuses on the manufacturing of composite equipment, that is widely used in marine and automotive applications. Due to the complexity and size of the sheets, the geometric characteristics of the molds, the high repeatability of the process, and the limited yet present exposure to chemicals, ergonomic challenges arise. TRYGONS, the end-user, envisions a semi-automate process, towards reducing dependency on human factors, while enhancing business competitiveness.

Composite case main objectives include:

RTForm solution introduces an industrial robot for human-robot co-manipulation of composite sheets, enhanced with peripheral handling, intuitive programming, and interaction tools to support operators. The AR-based interfaces can enhance human-robot collaboration through mutual awareness of actions and reduce human errors via continuous augmented operator support.

Textiles Use Case

This use case focuses on the manufacturing of garment patterns, including the cutting and sorting of fabric pieces, before sewing together. The current process relies on skilled operators who manually cut the fabric, and label each garment with style markers. Challenges that arise are related to the delicate nature of the fabrics, the precision required, and the ergonomic strain in case of cutting large fabric pieces. Katty Fashion, the end-user, aims to an industrial solution that will enhance scalability and production efficiency.

Textiles case main objectives include:

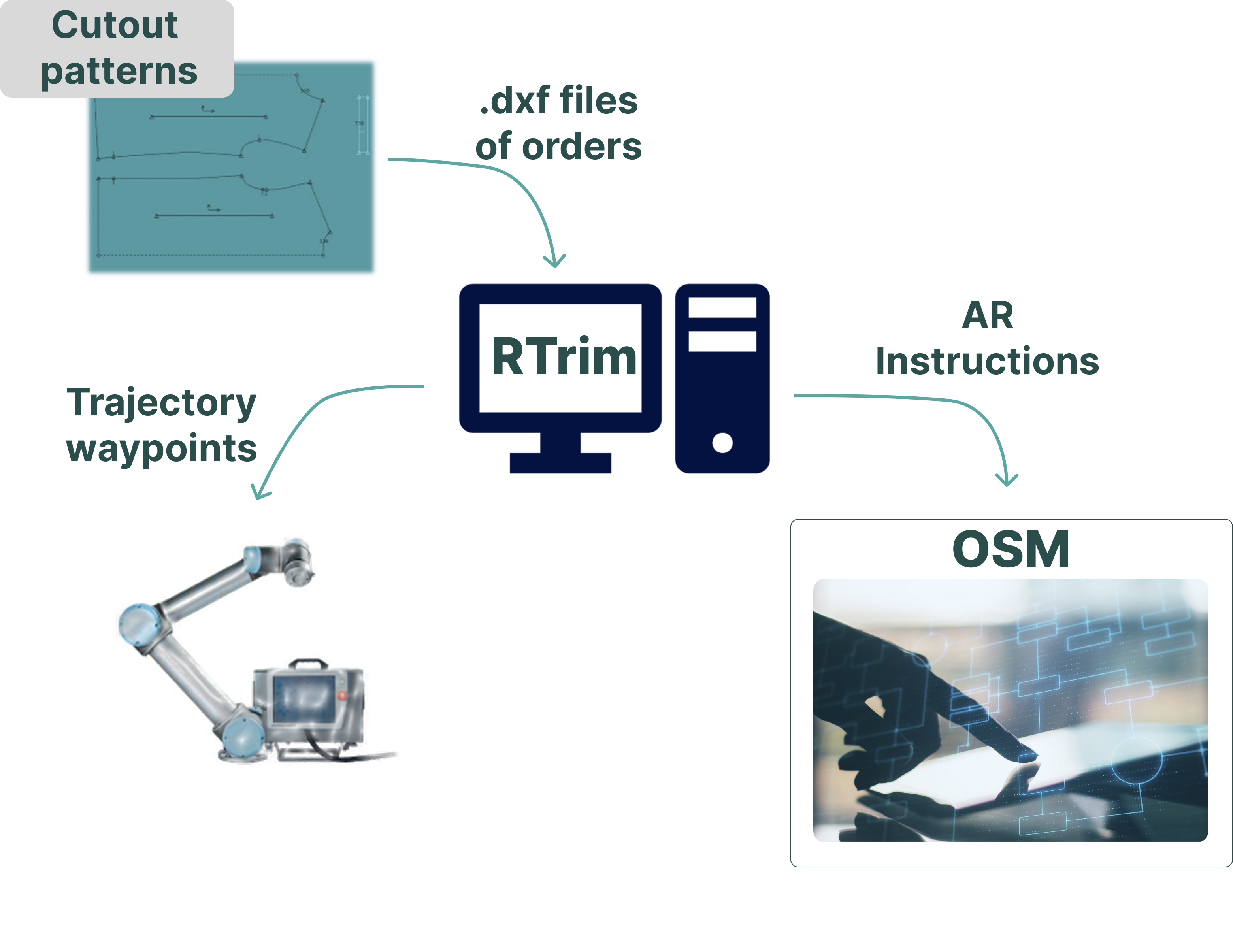

RTForm solution introduces the Rtrim toolkit, which translates the nested cutting pattern files into robot trajectories, allowing automation in fabric cutting. The AR-based operator support visualizes pattern configurations and provides continuous visual instructions, reducing human errors and improving cycle times by guiding the sorting of garments into bins based on predefined criteria. With this integration, the manufacturing process will speed up, leading to greater productivity, worker safety and competitiveness in the textiles & clothing sector.

Technologies

Human-Robot Flexible Material Co-Manipulation Toolkit (CMT)

The development of the Co-Manipulation Toolkit (CMT) will focus on enhancing human-robot collaboration through key capabilities, including operator input tracking, synchronization mechanisms for coordinated human-robot activities, and user-friendly code editing tools for easy re-programming. Additionally, the toolkit will ensure compatibility with the AR-based Operator Support Module (OSM) to further improve operational efficiency and interaction.

Solution objectives:

Intuitive AR-Based Operator Support Module (OSM)

The development of the Operator Support Module (OSM) module will prioritize smooth integration and user-friendly functionality. It will include APIs for data communication, the setup of digital environments, and the design of graphics for information overlaying. With the creation of a user-friendly interface, alongside the deployment of a cost-effective plug-and-play hardware kit, the design will prioritize usability and ensure high user acceptance.

Solution objectives:

CAD-Based Robotic Handling and Trimming of Textiles (RTrim)

The development of the CAD-based robotic handling and trimming (Rtrim) module aims to efficient automation and intuitive integration. It will include APIs for extracting cutout patterns from commercial nesting packages, translating CAD patterns into robot-native trajectory formats, and interfacing with robot controllers for precise trajectory execution. Additionally, the module will feature an intuitive programming interface, and AR-based pattern visualization, through a seamless connection with the Operator Support Module (OSM). The design will prioritize high user acceptance, ensuring usability and acceptance specifications for an efficient and practical solution.

Solution objectives:

Consortium Partners

Teaching Factory Competence Center (TF-CC) is oriented on providing Training and Innovative Technical services to the manufacturing industry. TF-CC is focused on enabling the knowledge sharing between academia and industry, exploiting the research results towards industrial applicability in pilots and creating added value for the services and products of manufacturing companies.

University of Dublin is actively involved in research and development projects related to a series of cutting-edge engineering and scientific fields and is particularly interested in collaborating with European industry and leading engineering firms. Its research portfolio involves process modelling & simulation, manufacturing operations Management and supply chain management.

GIZELIS ROBOTICS was established in order to offer state-of-the-art technology products-automation solutions to the global Industry. It is the newest company in GIZELIS Group, which is one of the oldest sheet metal machines manufacturer in the world. Its engineers and technicians have a long-standing experience on robotics, with numerous industrial applications under their belt.

TRYGONS S.A. is a pioneer composite parts manufacturer that utilizes state-of-the-art technologies for the design and fabrication of large and complex reinforced plastic parts focusing on mass production. The company offers products’ development from their inception and design up to their final materialization and market entry. TRYGONS has manufactured products for a number of industries and it is known for its cross-sector knowledge as well as the out-of-the-box thinking and innovative ideas.

Katty Fashion is a high-end bespoke fashion manufacturer with over 20 years of experience. Starting 2018 Katty fashion has started adapting the traditional textile manufacturing model to a more innovative, sustainable one focused on zeropreconsumer waste. This strategy is centered around digital collaborative design, product development and ondemand smart manufacturing. In a market characterized by highly manual, low digital processes, the model approached by Katty Fashion makes us the most innovative company in the region.

News & Media

Coming soon..

Contact us

Teaching Factory Competence Center (Project Coordinator)

info@teachingfactory-cc.eu

+30 2610 525 256